Hello lovelies,

Happy Monday! Did you have a good weekend? I had such a lazy one. I am sick again and tried to do as little as possible. Unfortunately I am not feeling much better so now I am still sick and feel like I wasted a weekend. Does that ever happen to you?

I’ve shown the progress of my polish racks on IG and had quite a few people interested in how I did it. I thought I would tell you how I made and what I learnt in the process. So let me start at the beginning. If you are going to use this post to make one for yourself I suggest you read the whole post first before gathering supplies. A few things will be all over the place but it will make sense in the end 😉

The wood.

I first made one biggish one on a Sunday afternoon. I hadn’t done any research so it was learning as I go. My first tip, close your wood wisely. The first one I made I made with melamine. As well as some other issues with this choice that I will mention later, the biggest one was the weight. The wood was heavy, which I first thought was a good thing as it also meant sturdy. It doesn’t. If you’re going to make a floor standing rack then it might be a good choice but hanging it on the wall, the weight becomes a factor. On my second run I asked for advice from the store where I bought the wood and ended up buying some kind of plywood. It was called plywood (it looks like layers of thinner wood compressed together to make a thicker plank) but I am not sure if there are different varieties. It was really sturdy but much lighter than the melamine was. The wood for one rack worked out to about R150.

The measurements.

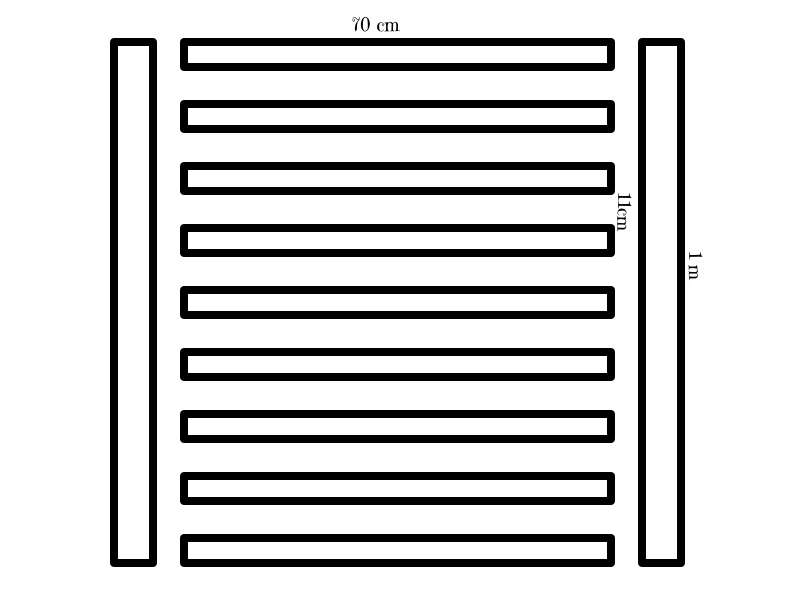

I mentioned the first one I made was bigger but I didn’t really take much into consideration. In the second batch I wanted to make sure that width wise I could fit them into the space I had available but also height wise that I could double them up if I wanted to or have it above a table or something standing against the wall. So the measurements I went with was: 70 cm (700mm) wide and 1m high. Of course the width ended up being a little bit more because of how I constructed it. When I went to the shop (both Builders and Timber City will do this for you although I found Timber City much more helpful in getting the most out of my wood). For one rack I got 2 x 1m planks and 9 x 70 cm planks. The dowels I added to the front of each racks was also cut by them. I asked them to cut them 70cm as well but I did have to sand them on the edges a little bit. You want them snug but not too tight that they end up bending (You can see this happened on the shelf 4th from the top on the photo above) So for one rack you will bee 8 x 70 cm dowels. The dowels are optional but I can tell you they have saved a bottle falling to floor quite a few times already. Let’s round that off. For one shelf you will need.

- 2 x 1m planks

- 9 x 70 cm planks

- 8 x 70 cm dowels (Optional)

All my planks are 8cm wide. That means the depth of the rack is 8cm which is plenty of space to easily move them around and even put 1 bottle in front of the other in case of duplicates. Depending on how far to the front you put your dowels if you put them in.

Paint / colour

When I made the first one from Melamine, the guy at the store told if I wanted to paint it I would need a special primer. I then looked at the price of paint and thought a bottle of spray paint will be cheaper. I also didn’t think I would need a primer if I used spray paint. I did not need a primer at first but once it was dry and I start moving it around I noticed it was much easier for the paint to chip or flake off. I also ended up needing about 4 cans of spray paint which ended up costing a few rand more than the paint would’ve been. When I did the second batch and I knew I was going to do a few racks I opted for paint. I could choose the colour I wanted and it went much further than the can of spray paint went. So first tip. If you are not using the plywood (and choose melamine) be aware of how paint will affect it. Second tip: Buy the paint. It will look like it will cost more but the paint will go so much further than the spray paint. I did use a wood primer (which was called pink primer 😉 ) and only needed one coat of paint. I also really wanted the leopard print on the outside and found this trick by accident when doing the first one. I used duct tape. They come in the coolest patterns and colours and I figured the durability will just add to the strength of the rack. Of course, it wasn’t needed but it looked so cool I had to do it. It was also really easy to apply it. I did paint the wood first and once it was dry I went to work with the tape. Remember, if you use tape on the outside you don’t have to paint the outside. Another advantage of the tape, it hides all the screws you used to assemble it. I assembled the whole rack before painting (the thickness of paint might just affect putting it together) but if you are going to add dowels I do recommend painting them first, painting the rack first and THEN adding the dowels. Painting them with the dowels attached was not fun. I bought 5l pink paint because I also used it to paint the wall and my desk. I still have half of that 5l left after painting the wall, the desk and 7 racks. I would say a 1l paint would’ve be more than enough to paint all 7 racks. This will be just under R200. (I bought it from a general shop, I am sure you can get this much cheaper if you go a paint store or even shop around. When painting the house we found similar paint in colour for much less from Shave). If you only make 1 rack you can even look at sample pots of paint. I saw these at Shave for a fraction of the price too. The primer was less than R50. I bought my duct tape for R50 a roll and you can do about 1 and a half racks with 1 roll. I also did not hunt for the cheapest price here and you might be able to get it cheaper.

Construction

Ok, so now you have 2 x 1m planks and 9 x 70cm planks. I lined up one 70cm plank with the edge of the 1m both top and bottom. In other words, the top and bottom planks were on the inside of the 1m plank. That means that the other 7 x 70cm planks will also fit on the inside of the 1m planks. If you fit the top and bottom 70 cm planks to the top and bottom of the 1m planks the width will be different and then the ‘inside’ 70cm planks will not fit. In that case you will have to cut off the width of the plank on both side. Even though the planks were 70 cm wide my shelf ended being 73.5 (or there about) wide. Each plank is about 1.6cm wide. Here is an image that might help

The space between each shelf is 11cm. Remember though it is shelf – 11cm – shelf – 11 cm etc. So the width of each plank is again important here. What I did is once I had the outside frame done, I lay it on it’s side, measured 11cm and then added 1 plank to measure the width. I drew a line on each side of the plank and then from the end of the plank I measure another 11cm and added the plank back for measurement, drew a line on each side and carried on this way till I got to the end. I then turned it around and did the same on the other side. One thing to remember, start from the same side (top or bottom) on bother sides you measure. Also, if your frame is not perfectly lined up this will also change the measurements. On one or 2 of my racks where the planks joined on the outside frame it wasn’t level and off by 1 or 2 mm. I still measure the same way. These lines will be a guide when you are attaching the planks. I used a small level to make sure each plank was straight but of course, none of them are 100% perfect. I just figured no one was going to walk around checking my works. 😉

For the construction I used small 3mm or 3.5mm screws of about 25 or 30 mm long. The packet was labeled ‘chipboard screws’. I was very paranoid about my racks falling apart and waking up to a hundred broken polish bottles on the floor so I used 3 screws at every ‘join’. The first time around I used nails and hammered them in but found a lot of splitting on the wood. When I bought the wood for the second batch I was advised to use screws rather. On my first attempt I once again had some splitting (different than the first batch but splitting nonetheless). When asking the about it I heard that drilling a pilot hole first is the best way to go. So, final round this is what I did. I drilled 3 holes using a 3mm wood drill bit and then screwed in the screws. Once the frame was built it was much easier to do the inside planks. I would once again lay it on it’s side. Use the lines I made earlier to measure and hold the 70cm planks in position. Drill 3 holes and then screw in 3 screws. I then moved on to the next one. Once they were all done I flipped the whole thing over and did the same on the other side. This time however I used a level to make sure each shelf was level and straight. I later in the process figured out that it was easier to do just the middle screws on the one side, flip the whole ting over and using either the level, the 11cm measurement guide or even just your eye if you feel confident in that to do the same on the other side. Doing only the middle screw again. With just the middle screws done they are still able to be tilted backwards and forwards if it isn’t completely straight. With the middle screws done it is also holds the plank in place and then it’s quick work to go back and add the other screws. How many screws and how you do it is completely up to you. You will very quickly find the way that works best – and easiest – for you. It’s most important to try and keep the edges level and make sure the shelves are straight and level.

The dowels, it doesn’t really matter how thick the dowels are you use. I didn’t want them to be super thick but I also took thick enough keeping the screws in mind. While trying to screw the first dowel in I realised it wasn’t going to work. If you are off by 1mm the screw will break through the side off the dowel. I ended up using glue that is for wood and porous surfaces and just glued the dowels in place. It wasn’t go to hold weight and it wasn’t holding the shelf together so I figured it would be fine with glue. I measure 1.5 cm up from the bottom of the shelf and 1cm in / deep on both sides and used this mark to glue the dowels. This made sure they were pretty even when looking at them from the front.

Now comes the important part: hanging the racks on your wall. I used these L shaped brackets.

I used 2 on the top shelf and 2 on the second from bottom shelf. These are sturdy and using 4 per rack meant I didn’t have to worry about waking up to all that polish on the floor. It was my biggest fear I tell you!! My biggest tip for this part. If you are using the same brackets, the hardest part was attaching these to she shelves after I had assembled everything. In hindsight, I would’ve attached these brackets after I had assembled the frame OR before I even start assembling anything. Just make sure you use the right planks in the right spot. That 11 cm gap isn’t very forgiving but if you have a short screw driver or even better, a ratchet type screw driver then it will make it a lot easier. If you do attach these brackets before assembly you have other concerns to worry about. You have to make sure you don’t paint them and you have to make sure you use the planks you attached them to in the right position. Keep in mind I had 7 racks so attaching them all after the fact in that 11cm gap was not fun but if I was only doing one rack it probably wouldn’t have been such a big deal. Basically, there are pros and cons to attaching them before or after. Do what is easiest for you. To attached these I used screws that would fit in the hole of the bracket (I had a friendly store person help here here). The 2 that goes into the plank I used very short screws. Remember the plank is about 1.6cm thick and you don’t want the screw to go right through. I used 1.6cm long screws (the thickness of the bracket will prevent it from going through) Unfortunately I can’t remember how thick they were but I suspect it was a 6mm. For the 2 that go into the wall I used the same thickness (I think 6mm) and about 4cm long. Remember you will need wall plugs as well. So buy the screw / plug combination. For one rack you will need 4 brackets, 8 screws to go into the plank and 8 screws that go into the wall.

Done!

And that is pretty much that. Now, let me wrap it all up for you.

To make 1 polish rack like mine you will need:

- 2 x 1m planks (8cm wide)

- 9 x 70 cm planks (8cm wide)

- 8 x 70 cm dowels (optional)

- 54 screws – I used 3mm x 25mm but you can also go as far as 3.5 mm and 30mm. (to work this out: 9 ‘joins’ each side = 18 x 3 screws at each join = 54. If you only use 2 at each ‘join’ you will need 36 screws)

- 4 x ‘L’ shaped wall brackets

- 8 x screws – short, no longer than the thickness of your plank, usually 1.6cm / 16mm. Check with the store what the thickness of these screws are, I think it was 6mm. You want them to fit properly into the hole of the bracket.

- 8 x wall plugs and screws – same thickness as above and about 4cm long. Give or take a cm.

- Glue to attached the dowels. Make sure it is usable on wood / porous objects. Bonus if it dries fast, you could consider using a hot glue gun but just be aware of any chunks of glue that might stay behind. This will be visible.

- Paint of your preference

- 1 roll duct tape in pattern of your choice. (optional, you can paint the outside if you want as well)

- 1 x 3mm drill bit (wood)

- drill bit for the size of the screw you will use on the brackets to go into the wall.

- screw driver to fit the screws you use – I use an electric screw driver with all the different bits I could need

- Drill – I used a cordless drill but either will do.

- 1 – 2 hours to assemble. I could do 1 in about 30 – 40 mins by the third one but it took a bit longer for the first.

- Paint and dry time.

You can make this in any size you want of course. You can even measure the space available to you and work according to that. Or if you just want 3 / 4 / 5 shelves you can do that too. One thing to remember when it comes to the height is the spaces between. 11cm is a perfect size, it is big enough to fit any of the polish bottles in the brands I have and enough space to lift them in or out as well. So if you want it shorter I would suggest using this way to work it out. Let’s say you only want 4 shelves: the thickness of the plank for the top (1.6cm) + 11cm + one plank thickness (1.6cm) + 11cm + thickness of plank (1.6cm) + 11cm + thickness of plank (1.6cm) + 11cm + thickness of plank at bottom (1.6cm) = 52cm. So you would need 2 x 52cm and 5 x width to make this rack. Also remember your bottom shelf will also be the bottom of the rack. That means that a 4 shelf rack will have a top, a bottom and 3 planks in-between.

I hope I am not missing anything. If you have ANY questions please feel free to shout. You can either leave a comment or email me and I promise to get back to you as soon as possible. If you do end up making one I would love to see it. Please let me know by tagging me on IG or twitter or posting it on my FB page. I would really love to see. I really enjoyed making these. I will admit I was completely over it by the time I had done 7 but it was SO worth it. It was cheaper to make 7 than it was to buy 1 close to this in size (but smaller). I could make it exactly how I wanted to and in the colours I wanted to. In hindsight I wish I had used the duct tape on the dowels as well. They would look so good in leopard.

Oh and in case you were wondering how much polish you could get on one rack, let me give you a rough idea. I can get between 20 (bigger bottles like china glaze / OPI) and 25 (smaller bottles like Essence / Hean) on each shelf. That means I could get between 160 and 200 polishes per rack. That’s not bad right?

I would love to hear what you think, if you’re going to try making one or even if you have already made one, what tips and tricks do you have?

Thanks for reading,

Well done. It looks amazing ?

Thank you so much Sibahle.